By listening intently, we can develop unique, value-added solutions for you, our customer. Our goal is to grow long term relationships by providing quality service before, during, and after the job. Dialog has developed and trained all of our personnel giving them the experience and latest equipment to perform pipe recovery, logging, and completion on existing wellbores. We have invested in state-of-the-art downhole tools, equipment and accessories, and software answer products in order to improve service capabilities and service quality.

The Dialog backoff service applies left-hand torque in the pipe while the string shot is detonated. The torque is applied at the neutral weight. The explosive percussion causes the joint to unscrew. Using the collar locator, the backoff can be verified before coming out of the hole.

Criteria that affect the string shot construction are:

The pipe size and weight, depth of stuck point and fluid weight are needed to determine the strength of the string shot and temperature is required to determine type of primacord and detonator. A string shot can be run in the annulus and backoff pipe from the outside.

The Dialog chemical cutter service is used commonly in wireline pipe recovery operations. It cuts through coiled tubing, tubing, casing, or drill pipe with a cut that does not have a flare and does not distort the pipe ID or OD. This service allows fishing operations to proceed without the need to mill the top of the fish. The cutter is designed to operate in extreme pressures and temperatures and does not leave any debris in the hole. Large diameter versions are available. The chemical cutter service does not require torque to be applied to the pipe which is particularly useful in applications where the pipe will turn freely but will not pull free.

The Dialog free point service uses an electromechanical tool designed to measure the amount of torque and/or stretch of a given length of tubing, coiled tubing, drill pipe or casing.

During drilling, completion, or workover operations, the pipe can become stuck in the borehole and the Free Point Tool identifies the stuck point so the pipe can be backed off or cut.

With tool sizes that vary from 11/16” to 1-11/16”, magnet, spring and motorize anchor options (Dog Tools) for wells with scale or Paraffin as well as high temperature versions. Dialog can free point all sizes of tubing, coiled tubing, drill pipe or casing.

The Dialog jet cutter service is intended to cut coiled tubing, tubing, drill pipe and casing. A jet cutter uses various size circular shaped charges to make a radial cut in virtually any size pipe. The jet cutter service however is most often used for cutting tubing, coiled tubing, and casing. The typical jet cutter will leave a flare on the pipe however premium low swell cutters are available. If the cut pipe is going to be fished, it is necessary to smooth the top end of the fish with an internal mill. Jet cutters must be matched to the size of pipe being cut and restrictions in pipe often will limit the ability to use a jet cutter.

The Dialog gamma ray service measures naturally occurring gamma ray levels within the well bore. Available in both a stand along service and also in conjunction with our explosives operations, the log is used for identification of the formation lithology. The service is also used as a correlation device between logs when the tool is run in combination with other tools.

The dual fire gamma gun service allows gamma ray correlation to occur during explosive operations. With dual fire capability, the tool can be run with strings with multiple guns firing on positive and negative polarity. This service is available in high temperature and high pressure applications (HTHP).

Gamma ray and gamma gun tools are available in diameters for 1.69 in. to 3.13 in., pressure ratings up to 20K psi, and temperature ratings up to 500 degrees F.

Dialogs TCP service offers operational Efficiency. TCP allows the well operator to perforate long, or widely spaced, intervals simultaneously on a single trip into the well rather than having to make multiple runs on wireline. This service can be performed off of stick or coil tubing.

The difference between TCP and wireline-perforating rig time depends on interval length and the number of wireline descents vs. the additional time to position the string and to ready the well for TCP operations. However, TCP exposes the gun to the well environment longer than wireline perforating, a concern in high-temperature operations. TCP gives the well operator an opportunity to perform a flow test immediately after perforating. Impulse type testing techniques can be used to identify the extent of wellbore damage before large investments in stimulation or gravel packing are made.

Retrievable Bridge Plug Dialogs RBP is a high performance monobore plugging device which can be set at any required depth in the tubing or casing. The plug is deployed, equalized and retrieved using conventional well intervention methods. Deployment is achieved in one run, as is the subsequent equalization and retrieval of the plug. This enables a reduction in both well intervention risk and subsequent operational cost.

The Retrievable Bridge Plug features bi-directional slips which anchor the plug to the well casing prior to pack-off of the element to form the pressure seal, making it ideal for cross flow applications.

Dialog offers the Split Shot cutter service which is a vertical shaped charge jet cutter positioned across the collar to be cut and held in place by a magnetic decentralizing tool. After detonation, the collar is cut or split allowing the pipe to be pulled free. Unlike most jet cutters that have a flared cut, the cut of the Split Shot is clean and allows the pipe to be pulled free without any additional drag or damage to the casing. With a smooth cut and no debris left in the hole, operations may continue without the need of additional milling operations.

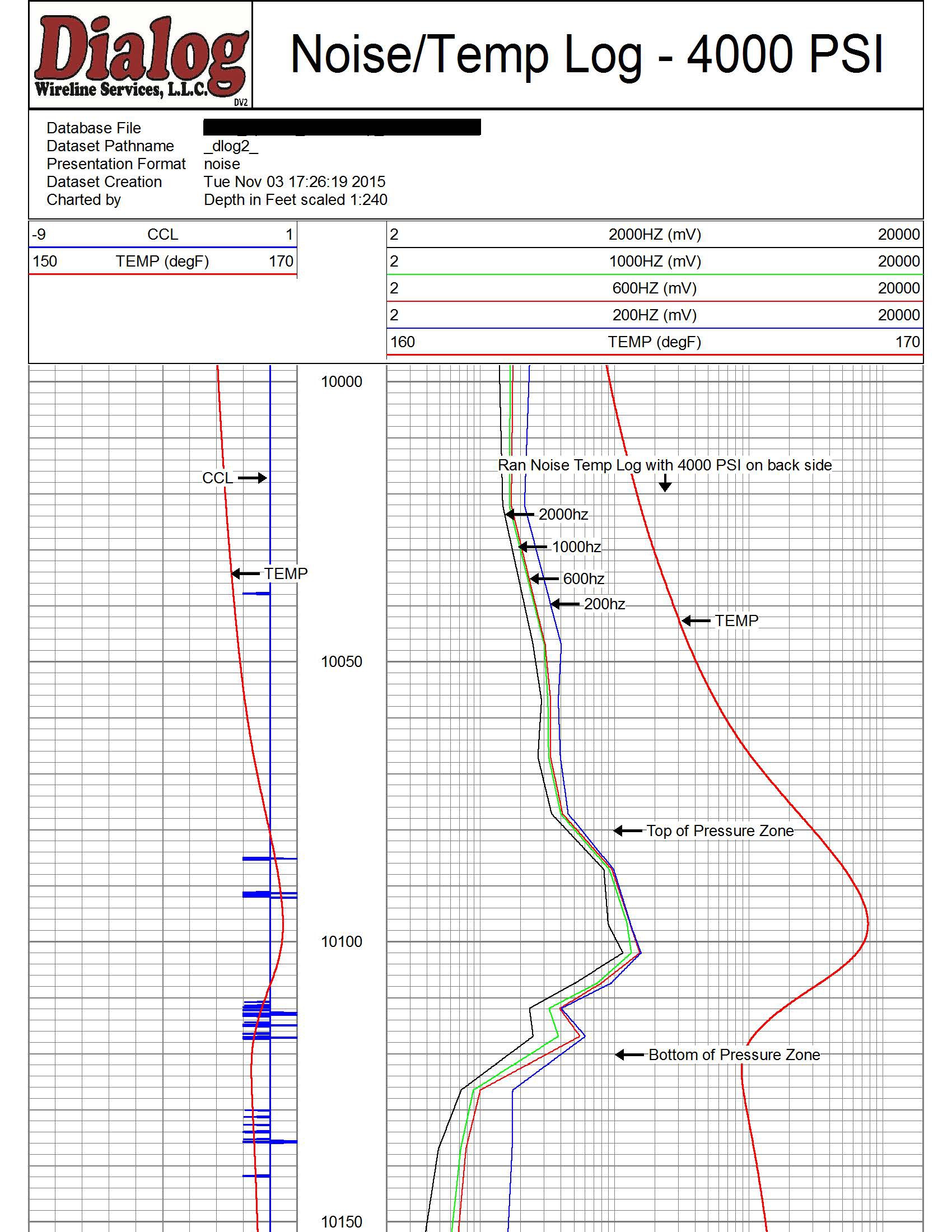

Noise/Temperature Log The noise-logging tool “listens” passively to downhole noise, for example, from gas bubbling up through liquid in the wellbore. Behind pipe, a channeling flow often passes through cramped spaces and constrictions. These “tight spots” cause high velocities, sudden pressure reductions, and significant flow turbulence. The noise tool listens to the noise associated with the turbulence.

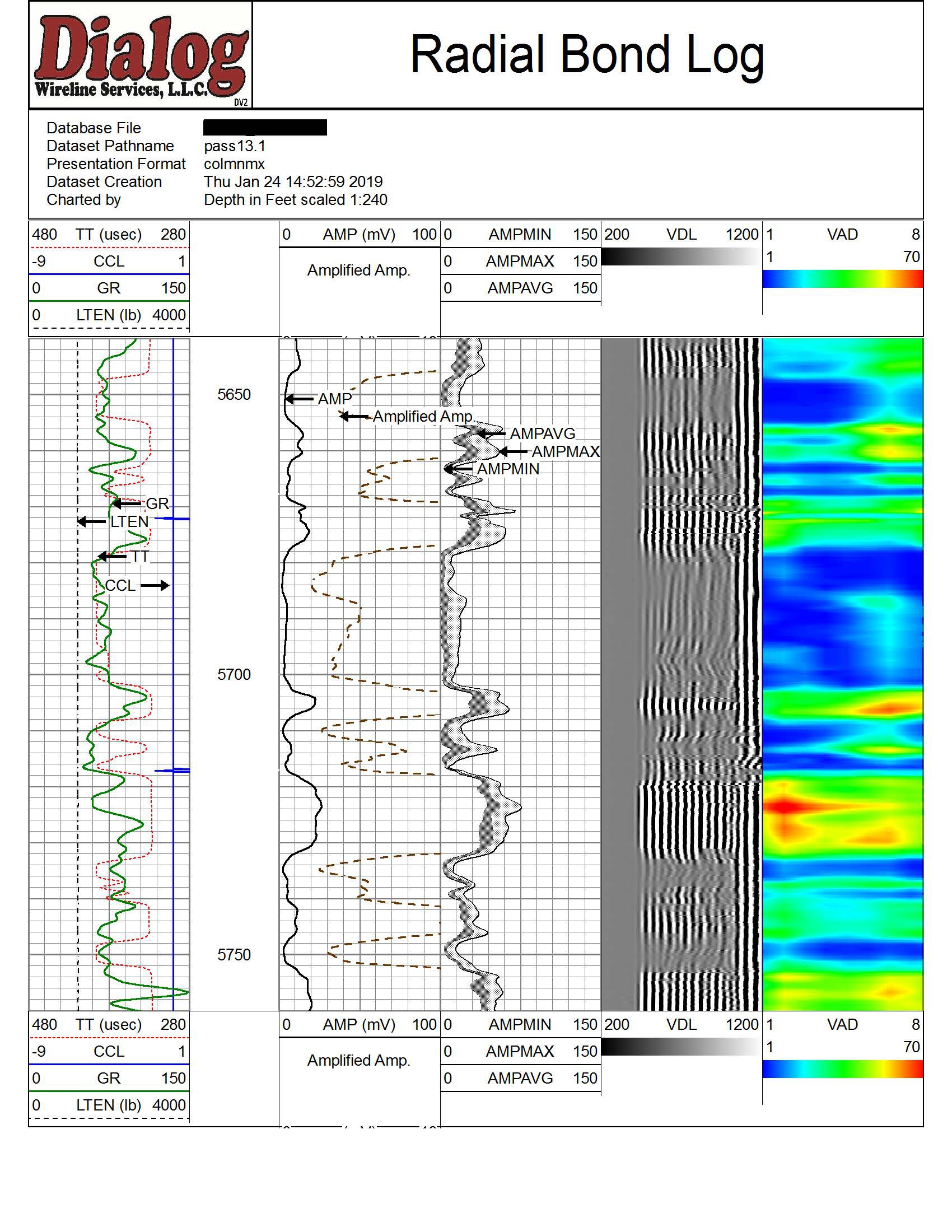

The Dialog Cement Evaluation Service is used evaluate the cement bond and the existence of hydraulic zone isolation. Depending on the applications, the cement evaluation service is performed with a single receiver bond tool, dual receiver bond tool or a radial bond tool. The single receiver tool utilizes a single transmitter and one receiver spaced at three feet. The dual receiver tool utilizes a single transmitter and two receivers spaced at three and five feet. The radial bond tool utilizes a single transmitter with radial receivers at two feet along with standard receivers spaced at three and five feet.

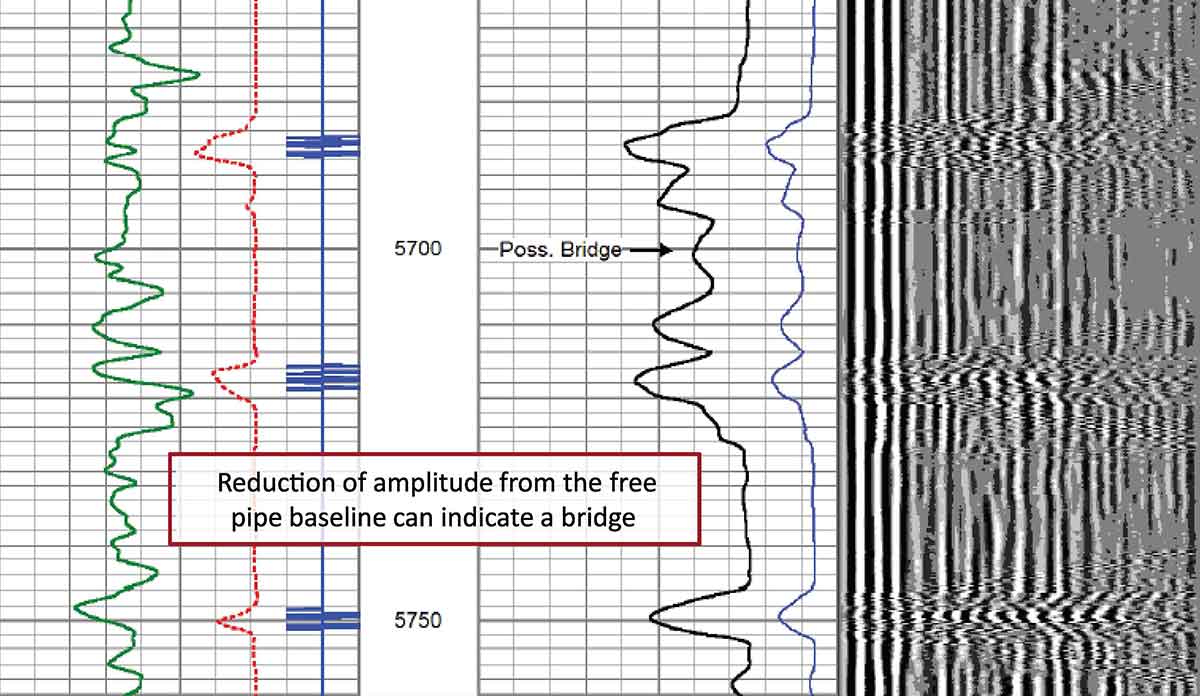

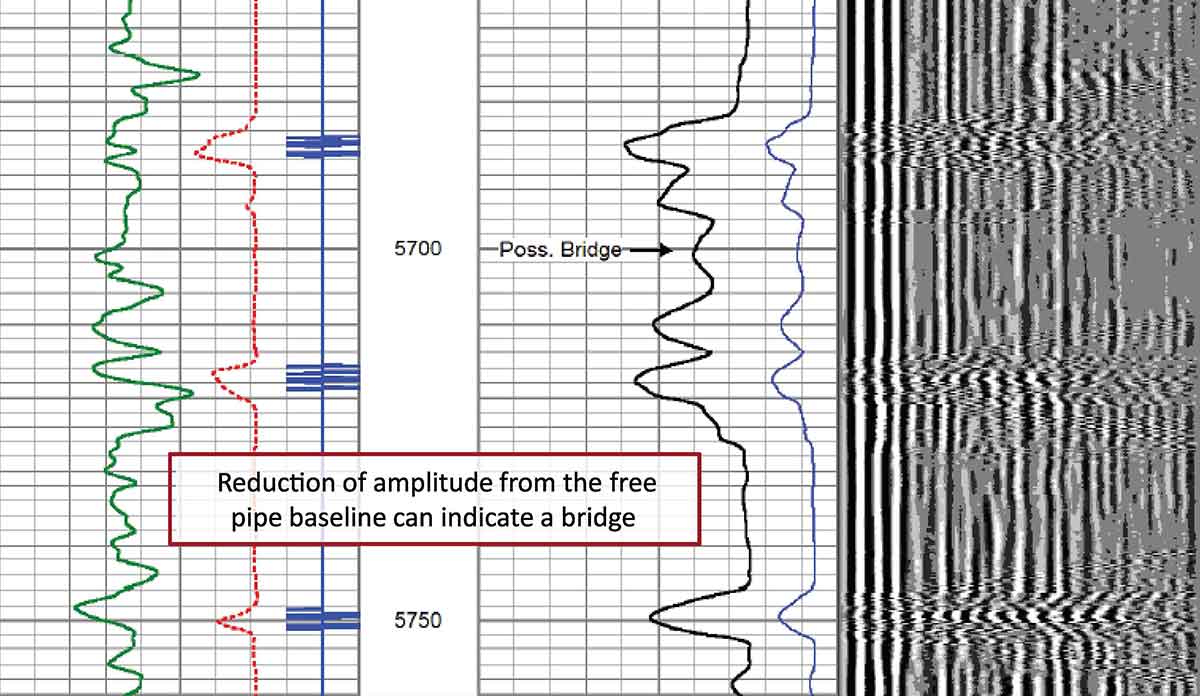

The Dialog stuck pipe log service uses a sonic measurement to provide an evaluation of a stuck pipe string. This service can be performed through drill pipe, casing or tubing to identify problem areas. Similar to conventional cement bond log measurement, high amplitude measurements indicate free pipe and low amplitude measurements indicate stuck pipe.

The stuck pipe log service is unique from the free point service, because the stuck pipe log service may be used to determine multiple stuck points throughout the well whereas the free point service can only identify the shallow most stuck point. The stuck pipe log service gives additional information that allows an informed decision to be made as to how to best proceed in the pipe recovery operation.

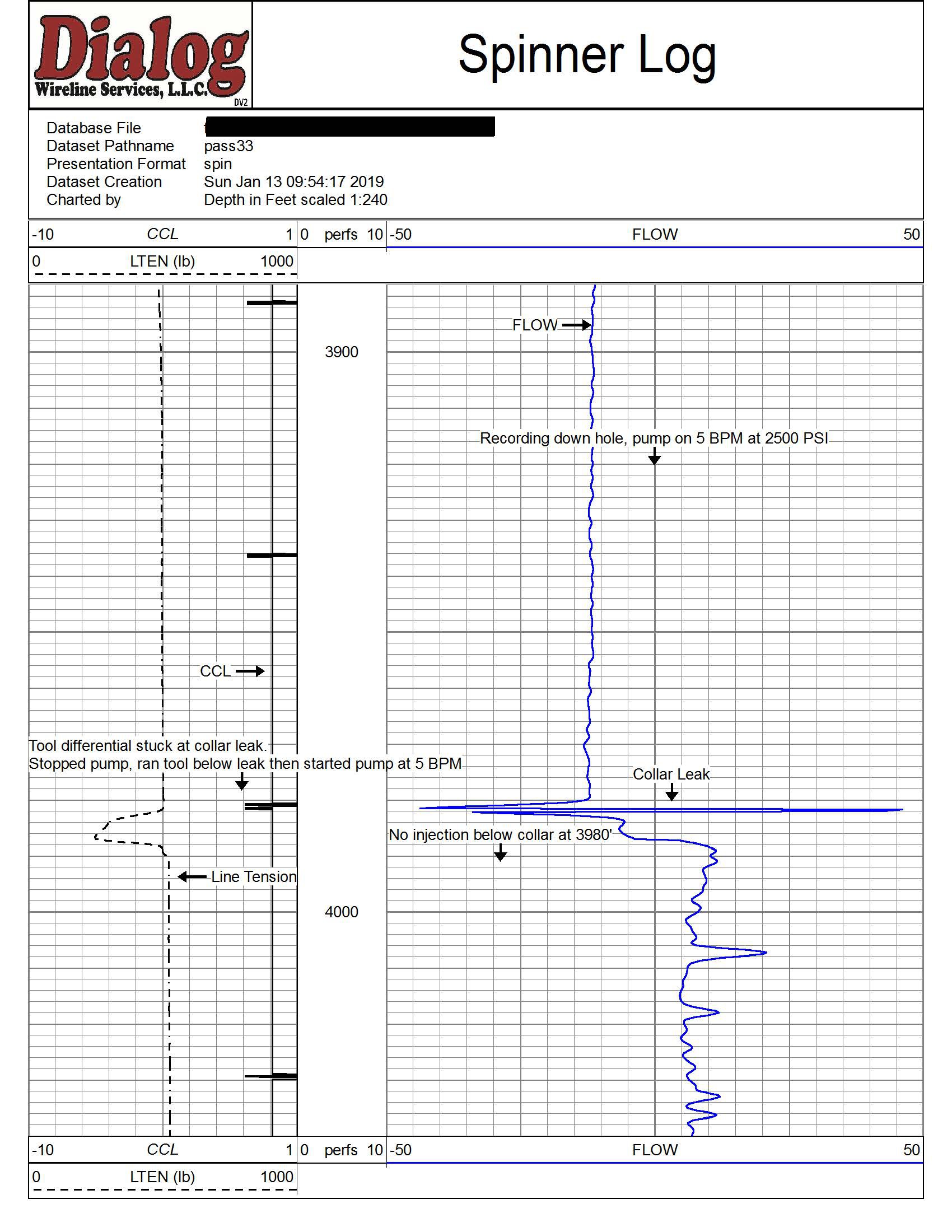

Dialog Wireline’s spinner/temperature survey Production Logging Tools measure reservoir performance, identify fluids, and detect leaks in connections or in situations that are too small to detect by caliper tools. This saves an enormous amount of time in lieu of relocating plugs and packers off tubing.

The Dialog stuck pipe log service uses a sonic measurement to provide an evaluation of a stuck pipe string. This service can be performed through drill pipe, casing or tubing to identify problem areas. Similar to conventional cement bond log measurement, high amplitude measurements indicate free pipe and low amplitude measurements indicate stuck pipe.

The stuck pipe log service is unique from the free point service, because the stuck pipe log service may be used to determine multiple stuck points throughout the well whereas the free point service can only identify the shallow most stuck point. The stuck pipe log service gives additional information that allows an informed decision to be made as to how to best proceed in the pipe recovery operation.

Sign up for our newsletter to receive the latest updates and insights on our services and industry trends.